MZ-4200 Hydraulic Rotating wood grabber

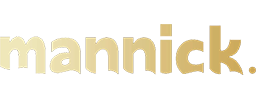

MZ-4200 Wood Grabber Parameters

| Arm extension length | 4.2m (hard link without expansion) |

| Grab weight at arm span of 2 meters | 1200kg |

| Column rotation torque | 11KN. m |

| Column rotating structure | Flange type+welded box rack oil cylinder rotary support "Gear+rack adopts local carburization process" |

| Number of rotating oil cylinders | 4 pieces (Italian imported oil seals) |

| Rotation angle | Left 190 °+Right 190 ° \ Rotation angle 380 ° |

| H-shaped support leg | 2 hydraulic support legs (different structural support legs can be equipped according to the vehicle) |

| Gripper | 360 ° unrestricted rotation |

| Arm form | Two sections are foldable, hard linked, and non expandable. |

| Whole machine weight | 760 kg |

| Installation space | 500 mm |

| Arm fully extended 4.2 meters grab | 700kg |

| Hydraulic system flow rate | 40 L/min |

| Recommended power | 11KW |

| Random accessories according to different installation requirements | All aluminum hydraulic oil tank, high-power 150-liter radiator (temperature controlled automatic start stop), high-pressure oil pump,2 hydraulic support legs, 2 hydraulic locks, installation bolts, and installation plates. |

MZ-4200 wood grabber Finished product graphics

Not only can it be installed on vehicles, but it can also be fixed in workshop buildings, ships, crushers, feeding machines, balers, biomass pellet machines, garbage stations, straw processing, and various equipment for loading and grabbing work.

Without real materials, I dare not showcase them:

Whole machine arm frame: Made of BS960 high-strength steel plate and CNC one-time forming bending process, greatly improving the structure of the arm frame to prevent bending.

Whole machine coating: Adopting specialized electrostatic spraying technology for engineering machinery, the metal surface is treated before coating using shot blasting technology to achieve a certain roughness on the surface of the workpiece, making it beautiful and changing the welding tensile stress to compressive stress, thereby improving the service life of the workpiece.

Rotary support: a welded gear rack rotary support developed independently by the company, with the advantages of preventing the breakage of overweight column gears, making it more sturdy, reliable, and durable than traditional cast boxes. The internal gear and rack processes all adopt local carburization, which not only increases the hardness and wear resistance of the teeth, but also ensures the toughness of the material. This process is difficult and costly, but it greatly improves its service life.

Oil cylinder: All use Xuzhou Yanhuang hydraulic cylinders, which are one of the supporting suppliers of domestic famous engine manufacturers. Pin shaft and sleeve: all made of brass and graphene shaft sleeves, which reduce wear, lubricate, dissipate heat, and extend service life.

Daring to showcase is the key to quality. We welcome on-site or video factory inspections.

1. Whole machine arm frame: Made of BS960 high-strength steel plate and CNC one-time forming bending process, greatly improving the structure of the arm frame to prevent bending.

2. Oil cylinder: All use Xuzhou Yanhuang hydraulic cylinders, which are one of the supporting suppliers of domestic famous engine manufacturers.

3. Hydraulic oil pipe for the entire machine: using sleeve type white zinc pipe and American Parker rubber hose.

4. Rotary support: a welded gear rack rotary support developed independently by the company, with the advantages of preventing the breakage of overweight column gears, making it more sturdy, reliable, and durable than traditional cast boxes. The internal gear and rack processes all adopt local carburization, which not only increases the hardness and wear resistance of the teeth, but also ensures the toughness of the material. This process is difficult and costly, but it greatly improves its service life.

5. Hydraulic valve system: For the new 1-control 3-operation operation, it is convenient and flexible, improving work efficiency while ensuring operational safety.

6. Slewing support: At the flange and support legs, it is a new type of reinforced base that increases the stability of grabbing operation. The structure is beautiful, sturdy, and durable.

7. Equipped with 2 hydraulic support legs, original reinforced hydraulic radiator, and original hydraulic oil pump.

8. Equipped with a 5-ton 360 infinite rotation motor, it can adjust the position of the grabbing object at will, making it convenient and fast.

9. The square tube structure has an upward and downward climbing ladder, with beautiful streamline and safe and sturdy structure.

10. Whole machine coating: Adopting specialized electrostatic spraying technology for engineering machinery, the metal surface is treated before coating using shot blasting technology to achieve a certain roughness on the surface of the workpiece, making it beautiful and changing the welding tensile stress to compressive stress, thereby improving the service life of the workpiece.

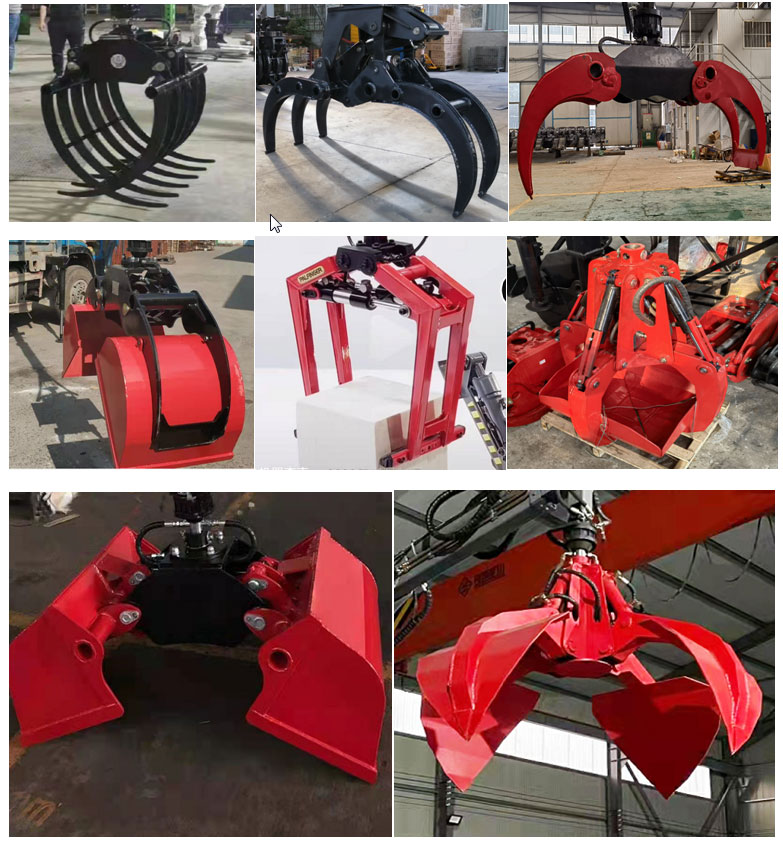

The purpose, model, and size of the gripper can be customized according to your work needs. We provide more gripping solutions for the objects you want to grab.

Below are more case studies of grippers for reference only! ↓↓↓↓

Various grippers are for reference only, and we will meet your needs according to your various working conditions.

This wood grabber can be installed on various transportation vehicles, such as transport trucks, tracked transport vehicles, four different wheeled transport vehicles, able to grab wood, bamboo, trees, straw, sugarcane, sand and gravel, grass bundles, bricks, cement bags, scrap iron waste, steel bars, steel pipes, household waste, can be installed on fixed platforms or the ground. For more detailed usage instructions and prices, please contact our professional business manager for answers!